Whether or not you have a set of dough divider rounder in hand, you might as well keep on reading as your click is a clear sign of your interest in it. Our passage How to Choose Your Dough Divider explains everything you need to know about dough dividing machine.

And today, we are going to introduce the integration of dough divider and dough rounder. As a dough divider-centered production line, this integration is the recipe for productivity, consistency and high quality. No matter what field are you in, the retail or wholesale, as long as your business is related to dough and pastry processing, we recommend you to read this passage to know more.

How do dough divider rounder line help with production?

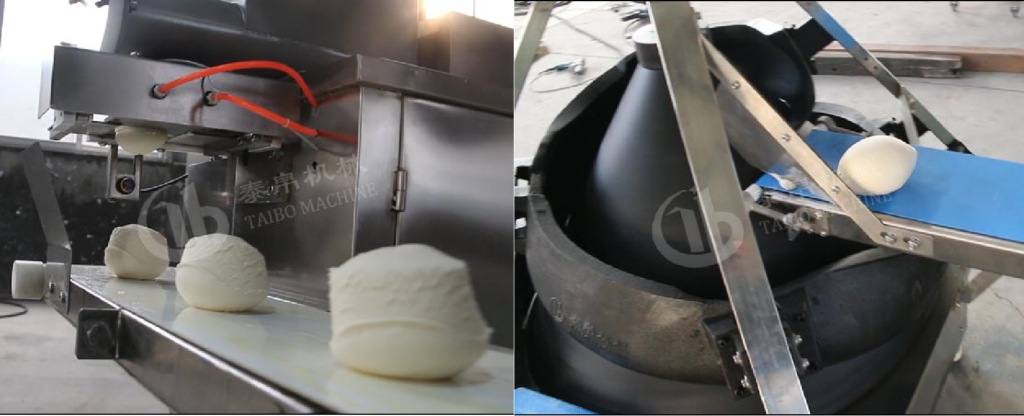

Dough dividing and rounding machines produce the highest quality and uniformity. It allows you to divide bulk dough into scores of dough balls with same weight quickly and easily and then shape every dough piece into ball perfectly.

The integration of automatic dough dividing and rounding eliminates the time for complex weighing and cutting process. It also relieves the labor to move thing around. With the high level of automation, you can increase the efficiency while ensuring all your breads, chapati, roti, pizzas, roll look and taste better.

However, it is worth mentioning that not all types of dough dividers are specially designed to be integrated with other dough preparation equipment. To know if your dough divider is connectable or learn more about the types of dough dividers, click The Different Types of Dough Divider.

Next, we’ll show you how the dough divider rounder line perform itself in different shops.

What can dough divider rounder line do in bakeries?

There are basically two types of bakeries: retail and wholesale bakery. Although they differ in scale, output and operation mode, they have one thing in common: they all produce more than one kind of bread.

Multigrain bread, wholegrain bread, baguette, bagel, and focaccia are all commonly seen. Some bakeries also have cookies, cakes, donuts, pastries, and pies. This implies that versatility should be on the list of priorities when choosing bakery equipment.

Though most bread recipes include two basic ingredients-flour and water, there are countless ways to enrich. The MF3 dough divider and MR3 dough rounder are developed to cope with the richness and variety in bread recipes.

The combination of dough divider and rounder is suitable for dough contains various ingredients such as yeast, sugar, oil, cocoa powder, matcha, etc. Plus, it is applicable to dough of high moisture content. Stainless steel divider and Teflon coated rounding cone ensure the dividing accuracy, rounding effect, easy cleaning and little wastage.

For small or medium sized bakery units, dimension of the equipment is a key factor when choosing the equipment. Therefore, compact dough dividing rounding equipment is absolutely necessary.

With small footprint and high accuracy, hydraulic dough divider is also a good option for space-deprived bakeries and restaurants. However, instead of working continuously, it can only process a limited quantity of dough at a time. After dividing, you have to take the dough portions out manually, which makes it less efficient and labor saving. In addition to these facts, hydraulic dough dividing machines cost lots of money compared with other dough dividers.

If you feel that a hydraulic dough portioning machine is too small to meet customers’ desire for delicious bread, a dough divider coupled with dough ball rounder which has larger output is a flawless Plan B.

What can dough divider rounder line do for Middle East cuisine?

Middle East cuisine has gained in popularity worldwide owing to its use of the local herbs and spices. You can even see Kebab in China’s restaurants. Most of our Middle East customers purchased the dough divider rounder line for the production of pita bread. Pita bread is a thin, round and uniformly sized flatbread which is versatile enough to be served with just about anything. It is similar to chapati, Arabic bread, chapati, naan and other staple foods all around the world.

The dough for pita bread contains low or moderate amount of water. For this kind of dough, people always choose mechanical dough divider, which is particularly suitable for tough dough and is reasonably prices. However, due to its structure and working principle, it can’t divide materials accurately.

Our dough cutting and rounding line divides large dough into 20-1100g and form them into dough balls with proper pressure. The weight error is only within 1%. Performance is guaranteed by quality SUS304 stainless steel and upgraded structure that give the machine great accuracy, durability and reliability. If you are looking for higher output and accuracy, we recommend this combination to you.

What do we suggest to dealers and distributors?

With our ripe experience and plentiful promotion materials of dough dividing and rounding, we can promptly provide the ultimate solution for dealers, distributors and their customers. With our own factory, we are capable of doing ODM, OEM and customization. Furthermore, the promotion materials like video and brochure can be adapted to suit specific requirements. If you have any demand, please feel free to contact.

Conclusion

If you’d like to know more about dough divider, dough rounder and bakery equipment manufactures, please click to read,

●What Are the Different Types of Dough Rounders?

●List of International Bakery Equipment Exhibition

2 Responses