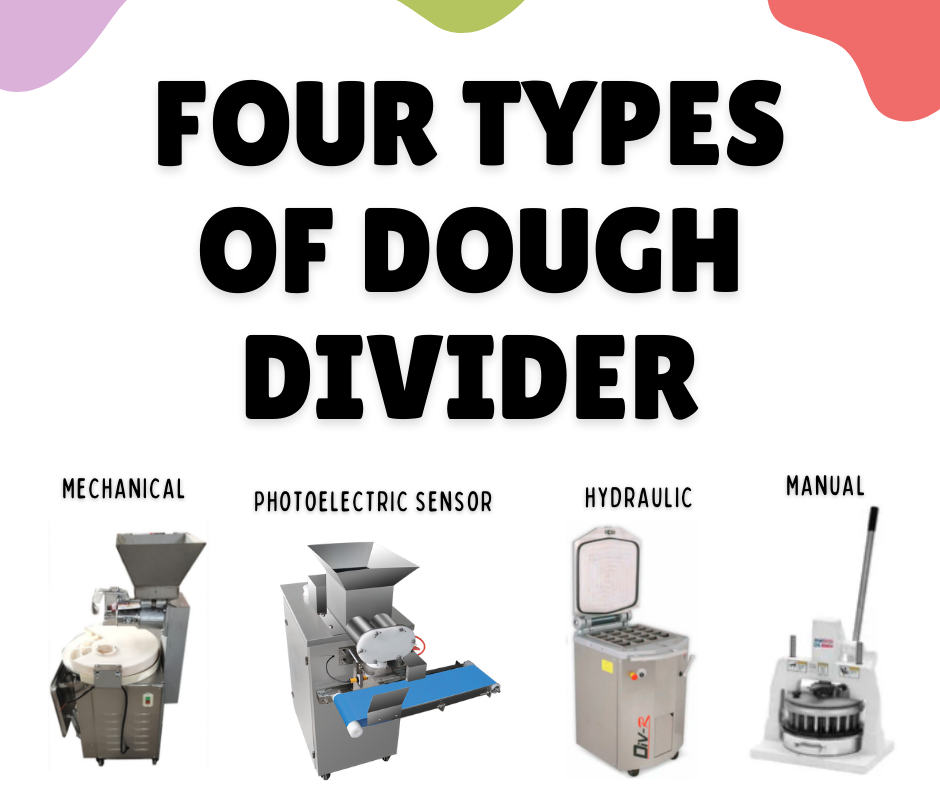

There are mainly four types of dough divider available now: volumetric dough divider, hydraulic dough divider, mechanical dough divider and manual divider. Dough divider cuts large quantities of dough into even weight and shape with a little time and labor. As a necessity in kitchen, a dough divider should never be a hasty decision to make. And that’s why we wrote this to guide to help you choose the ideal dough dividing machine for your business.

Overview: Differences between Various Dough Dividers?

Dough dividers help divide bulk dough into smaller pieces with uniform size and shape. However, there are various kinds of dough dividers available on the market now. Which one is the best for you? Which should be the last option to consider? This passage explains differences between the four different types of dough dividers and recommends the right one for various food businesses.

| Dividing Principle | Pneumatic Dough Divider with Photoelectric Sensor | Mechanical Dough Divider | Hydraulic Dough Divider | Manual Dough Divider |

| Raw Material | Soft dough, tough dough, fillings (sweet bean paste, tamarind paste, etc.) | Tough dough | Soft dough | Tough dough |

| Method of Discharging | Automatic and continuous | Automatic and continuous | Manual, in batches | Manual, in batches |

| Weight Range of Dough Portions | 2-800g | 30-200g*Source of date: Internet | 150-800g*Source of date: Internet | 30-100g*Source of date: Internet |

| Application | BreadPizzaChapati/Tortilla/Roti/Pita/Arabic Bread/NaanFillings | Chapati/Tortilla/Roti/Pita/Arabic Bread/Naan | BreadPizza | Chapati/Tortilla/Roti/Pita/Arabic Bread/Naan |

| Application Scenarios | Canteen, restaurant, bakery, commissary, pizzeria, chapati/ tortilla/ roti/ Arabic bread factory, snack factory | Canteen, restaurant, bakery, commissary, pizzeria, chapati/ tortilla/ roti/ Arabic bread factory | Canteen, restaurant, bakery, commissary, pizzeria | Home bakery, small bakery, small restaurant |

1. Pneumatic Dough Divider with Photoelectric Sensor

Structure: This type of dough divider is mainly composed of hopper, dough screw propeller, outlet, mold, photoelectric sensor, air compressor and conveyor.

How to operate: Put the bulk dough into the hopper. Being pushed and extruded by the two screw propellers inside, the dough comes out from the outlet. The cutter, being pushed by the air compressor, cuts the dough when it reaches certain position. Cut dough pieces are conveyed to the next machine or process.

Since the machine works on volumetric principle, weight of dough pieces depends on the length of the dough and the diameter of the mold. Once the photoelectric sensor detects the dough, the cutter will cut. Therefore, to change the cutting size, you need to change the mold or adjust the position of the sensor.

With these characters, it is better for the machine to divide the dough without fermentation. After dividing and forming, it’s time to let the dough pieces test and ferment.

Comparison: This type of dough divider has the most extensive application. It is suitable for not only soft but also tough dough. What’s more, it can handle mixtures like sweet bean paste and tamarind paste, which is incapable for other dough dividers. In terms of the size of dough portions, you are likely to pay more for extra cutting size if you choose a dough divider that comes with a cutter board or rounding plate. The cutter board and rounding plate are only designed for limited certain weight ranges. However, with this pneumatic dough divide, you can easily adjust the cutting size from 2g to 800g. All you need to do is pay a little for molds or adjust the photoelectric sensor.

With this outstanding versatility, it is a good choice for basically all dough-related business. It can help with the production of bread, pizza, cookie dough snack, chapati, tortilla, roti, pita, Arabic bread, naan, etc.

In a word, if you are looking a machine to divide a large quantity of dough or other solid mixtures into uniform size efficiently, this is the one, the pneumatic dough divider.

Pros: ①Accuracy. The weight tolerance is only ±1g to 1%.

②Weight flexibility. The machine can divide dough into 2g to 800g.

③Wide range of moisture content. The flour-water ratio is 10:5 to 10:7.

④Easy integration with other machines. With the hopper and conveyor, the dough divider is easy to be integrated with other dough preparation equipment like dough mixer, dough rounder, dough proofing box, etc.

⑤Multi-function. This dough divider is able to deal with dough and fillings like sweet bean paste, tamarind paste.

⑥High output: produce up to 80 pieces per minute.

Cons: ①Dough pieces have fixed shape and need forming afterwards. Unlike dough divider rounder that rounds the dough into balls automatically after dividing, this equipment produces cylindrical dough pieces. You need to form them into specific shape manually or automatically afterwards.

②The machine is made of SUS304 food-grade stainless steel, which is relatively expensive.

2. Mechanical Dough Divider

Structure: Main components of the mechanical dough divider are tray (or hopper for larger capacity), dough propelling and extrusion system, outlet, cutter, flour box, roller and rounding plate.

How to operate: Put the dough into the hopper or tray. The propelling system pushed the dough out of the outlet. Once the dough touches the roller, the cutter will rotate and cut off the dough. Dough pieces fall into the rounding plate made of stainless steel or plastic, depending on the price of the machine. Flour box above the roller spreads flour to prevent the dough from sticking to each other or the rounding plate.

Comparison: With its structure, this mechanical dough divider performs better with hard dough. It can not divide fillings or dough containing lots of moisture. Therefore, it is suitable for customers who produce steamed buns, pitta, chapati, Arabic bread, etc.

Just as the pneumatic divider, the mechanical type cuts dough volumetrically. However, without the photoelectric sensor, the divider is weak in accuracy.

Due to its material, the machine is relatively inexpensive. However, from a point of view of commercial value, this is a false economy. Just think about the time and money you are going to spend on finding a new machine.

Pros: Affordable price. As an entry-level dough divider rounder, the price of it is quite fair. If you don’t need the machine to be very accurate and you process single kind of product, this is the right choice.

Cons: ①Inaccuracy. The structure and cutting method result in the inaccuracy.

②Small range of cutting size. According to our research, mechanical dividers generally cut dough into 30g to 200g.

③Short lifespan. Most of these dough dividing machines are made of SUS201 stainless steel, which has a very weak corrosion resistance, thus a short lifetime.

3. Hydraulic Dough Divider

Structure: There are 2 forms of hydraulic dough divider: one is square and the other one is round. It comprises cover, cutter, cutter board, hydraulic power system and other components.

How to operate: Put the dough on the cutter board. Press and spread the dough evenly. Scatter some flour on the dough in case it sticks to the cover. Close the cover. The hydraulic system pushes the cutter up and the dough is then divided into portions according to the shape and size of cutter. Then the operator takes dough pieces out.

Comparison: Dividing without extrusion doesn’t break the structure and air bubbles of the dough. Thus this machine is particularly suitable for fermented dough or soft dough.

Given the pressure, the dough will be flat and thin. It would take lots of efforts to form the dough if you need dough balls. Thus the machine is not applicable to process the dough for buns, chapati, pizza or any round stuff.

To conclude, the square dough divider is more suitable for bakeries. It cuts dough into diverse shapes directly, which simplifies the production and creates more variety in products.

Pros: Shape flexibility. With cutters and cutter boards of different shapes, the dough can be divided into various shapes like triangle, diamond, etc. You can place the dough portions on the tray and put it in the oven directly. No forming is needed.

Cons: ①High price.

②Time and labor consuming. Instead of dumpling all mixed dough into the hopper, the operator has to cut bulk dough into smaller portions and them put the portion onto the cutter board. After cutting, the operator needs to take all the dough pieces one by one with hands, which is quite time and labor consuming, especially for large scale bakeries.

③Inconvenient to integrate with other machines. To use this machine, you have to divide large quantities of dough into smaller portions first. Then put the dough in, spread the dough evenly and then take dough pieces out one by one manually. It is difficult to automate any of these procedures to make the machine possible to be connect with other dough preparation equipment.

4. Manual Dough Divider

Structure: Manual dough dividers are available in both tabletop and standing varieties. Main components are dividing pan, knife head, handle, and cutting handle. Dividing pans are mostly round.

How to operate: Put the dough onto the dividing pan. Put the pan under the knife head. Lower the handle to pressure the dough. Lower the cutting handle to divide the dough into portions. Take out the dividing pan for next process.

Comparison: Hand dough dividers are perfectly suitable for small business.

Pros: ①Cost effective. This dough machine is perfect for small-scaled business like home bakeries, home restaurants, etc.

②Space saving. Compared with other kinds of dividing machine, hand dividers have smaller footprint. In your space deprived kitchen or bakery, it can easily fit in.

Cons: Time and labor consuming. All the procedures have to be done manually, which takes lots of time and labor. Moreover, when lowering the lever, it requires strong force to divide the dough. Otherwise you have to try multiple times to fully cut the dough.

7 Responses