Chapter 1 What is a Dough Rounder?

A dough rounder is a machine that forms dough pieces into dough balls with uniform shape and smooth surface. Given proper stress, dough pieces will be stretched, kneaded and rounded within the rounding guide, which is commonly spiral and concave. Generally speaking, a dough rounder creates uniformity and large output of dough balls with minimum manual labor.

A dough rounder is always the third machine in the production flow, after dough mixer and dough divider and before final proofer.

Besides breads, dough rounders are vital to products like pizza, chapati, roti, tortilla, Arabic bread, etc. Rounded dough pieces perform better in the next processes like pressing and baking.

Chapter 2 What Are 5 Types of Dough Rounders and How Does They Work?

1. Conical Dough Rounder

Conical dough rounder is the most common form of rounders. It is suitable for dough before proving. With consistent and relatively strong tension, the dough will be kneaded and well-rounded into dough balls. The main component of it is a cone with spiral concave rounding guide. For better performance, some manufacturers coat the cone and the rounding guide with Teflon, which is always used as non-stick kitchen equipment due to its anti-adhesion ability.

The friction of the dough pieces between the cone and the spiral rounding guide stretches and forms them into ball shape. The angle of the spiral concave rounding guide and the rotational speed of the cone will affect the shape of dough balls.

2. Cylindrical Dough Rounder

The main component of a cylindrical dough rounder is a drum in which there is a spiral rounding track. The friction of the dough pieces between the drum and the spiral track shapes the dough pieces. At the same time, dough pieces move upwards to the outlet will the rotating spiral track.

Source2: https://bakeryequipment.com/productdetail.php?ProductID=20539

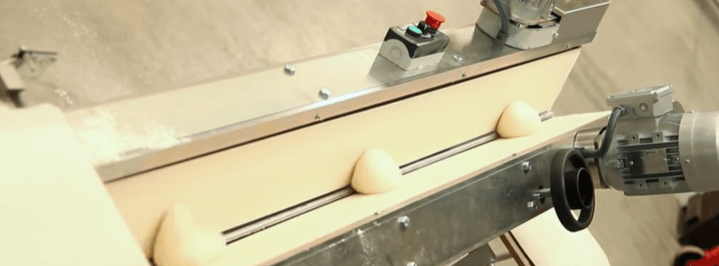

3. Belt Dough Rounder

There are basically two types of belt dough rounders. One type is mainly composed of belt and rounding bar above the belt. The dough is rounded while it is conveyed on the belt due to the friction.

The other type includes two belts positioned in the shape of V. Two belts running at different speed creates friction and thus the dough will be shaped into dough balls.

Belt dough rounders are always equipped with flour dusting system to prevent the dough from sticking to the belt, that is to say, belt rounders require regular cleaning and maintenance to remove the excess dough sticking and to result in great shaping performance.

The speed, angle and length of the belt and the bar, the amount of the dusting flour, etc. will affect how satisfyingly the dough balls are rounded.

4. Eccentric Dough Rounder

Eccentric dough rounder is mainly composed of cone, rounding track around the cone and conveyor belt. The circular movement with eccentricity shapes dough pieces into regular dough balls and dough balls will be received by the conveyor belt. This type of rounder is mild and gives less stress to the dough, thus it is suitable for dough after proving, saving the fermented structure of the dough.

5. Dough Divider Rounder

There are mainly two types of dough divider rounders. One type is composed of a volumetric dough divider and a rounding plate, which is plastic. The cutter divides the dough by volume and then divided dough pieces fall into the rounding plate. Rotating and moving in the rounding plate, dough pieces will be rounded.

The other type of dough divider rounder is shaped like a hydraulic dough divider. It divides dough into limited numbers of portions. Then the board and head rotate and shake to shape the dough into dough balls.

Source2: https://www.empirebake.com/

Chapter 3 6 Things to Consider When Choosing a Dough Rounder

1. Range of application

Take these 3 factors into consideration: the water content, the state, and the weight of dough pieces.

First factor is the water content of the dough. Be sure to remember that some rounders may not be suitable for dough of very high hydration due to its the material and structure.

Second is the state of the dough. The rounding process of some rounders are gentle while some are firm, damaging the airy structure. Are you going to round the dough before or after proofing? Think about it.

Last factor is the dough weight range. For example, some dough rounders are applicable to dough pieces of 30-300g while some are suitable for 30-1000g. Define the weight range of dough pieces that you want the rounder to round and choose the rounder that closely fits into that range.

2. Output

A dough rounder itself should be efficient enough to handle large-scale production. When used with upstream equipment like dough divider, it should match the divider.

3. Footprint

Size of the automatic dough ball machine matters. Be sure to check if there’s enough room for the equipment in your kitchen. A dough rounder with compact structure and small footprint is an ideal choice in busy and crowded bakeries or kitchens.

4. Material and quality

What we want in a dough rounder is safety, efficiency and durability. Therefore, food grade SUS304 stainless steel is a good choice. Several types of rounders may use plastic. The plastic, although light-weight and durable, can be damaged sometimes and need to be checked regularly. It goes without saying that stainless steel is more durable and solid, having longer service life. What’s more, the rounding system made of stainless steel can be coated with Teflon for better non-stickness.

Some dough rounders come with conveyor belt. Common material of the conveyor belt used in bakery industry is fabric, plastic and rubber. You have to ensure the conveyor belt is suitable for the environment and the ingredients of the dough.

5. Easy and quick to clean and maintain

The dough rounder requires proper cleaning and maintenance regularly. Make sure the cleaning and maintenance is easy and quick and it doesn’t have to be performed by a professional technician.

6. Consistency of the production flow

The dough rounder may be integrated with upstream and downstream equipment like dough divider, final proofer, etc. It’s important to make sure the rounder can be connected to other machines easily and smoothly. The capacity of machines in the production flow should be consistent. Furthermore, the less manual operation and adjustment involved during production, the better. Only in this way can you produce perfectly uniform dough balls for bread, pizza, etc.

Chapter 4 How to Clean and Maintain a Dough Rounder?

When it comes to cleaning, focus on the dough-contact surfaces like rounding system, belt, etc. Take our TBMR3 dough rounder, for example. After using, the staff should remove the flour with a bottle brush and remove the dough sticking on the cone, the spiral rounding guide and the conveyor belt with a wet clean cloth. With the non-stick material of the rounder, the cleaning will be very easy and quick. It requires little maintenance. If you still have questions about the cleaning and maintenance, you can look up to user manual or directly contact the supplier.

In terms of cleaning Taibo TBGR3 dough rounder, you can demount the rounding spiral and directly rinse it with a hose or high-pressure water gun. Click the video to see how fast and simple the cleaning is.

2 Responses